400 820 5059

150-2122-3752

400 820 5059

150-2122-3752

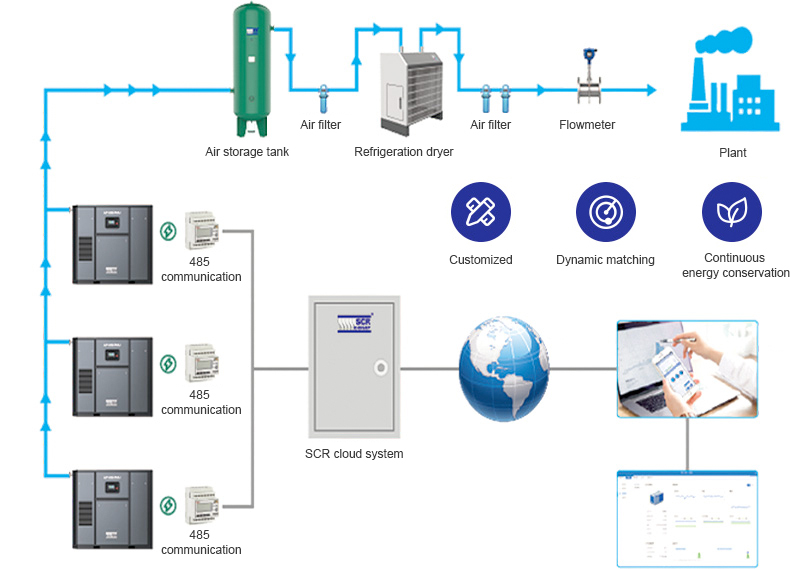

Digital support for refined station building management, measurable and manageable air cost

Digital support for refined station building management, measurable and manageable air cost

The professional requirements for management personnel on site are reduced, and our company’s professional staff will guarantee high-efficiency and reliable operation of the station building

We provide professionals for station building management and ensure long-term efficient and reliable operation

24H online monitoring to ensure reliable operation of machine

Reduce air cost and realize win-win cooperation through energy-saving reconstruction

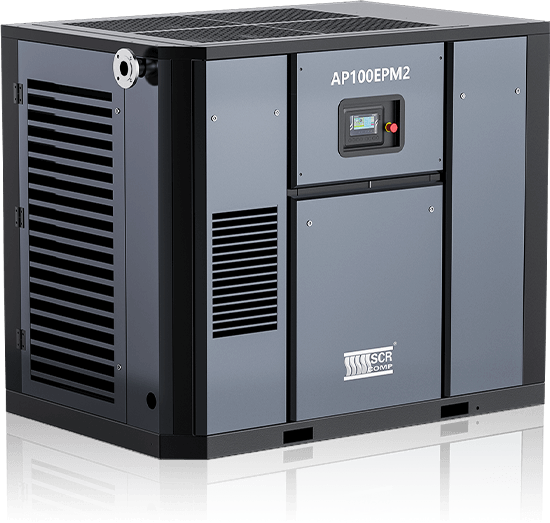

Customs compressor match your air demand

Automatic adjust air supply to meet air comsumption

IoT system help get real air consumption, help improve the operation of compressor

Keep innovation for better efficiency products

Guarantee the safe air supply to the factory operation

Preventative action keep compressor in good state

Automatic adjust air supply to meet air comsumption

Key parameter under real monioring

Intelligent warning if any abnormal sitution

Grasp the real-time operating status of the overall equipment cluster

Authorized people can access and get data remotely